Better by Design

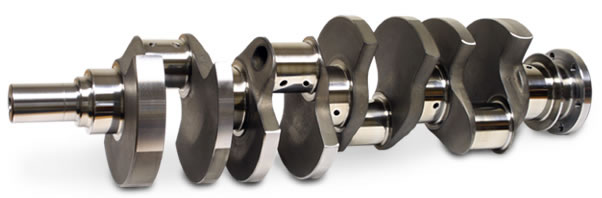

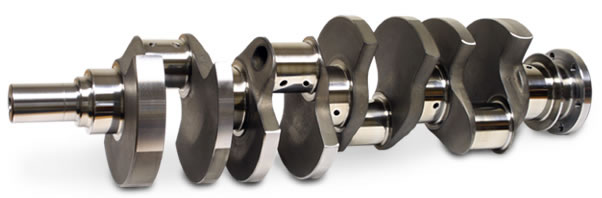

Crankshafts

- Compstar crankshafts begin their life overseas where they are forged using Callies owned dies. Not generic forging that other manufacturers use. You can be confident that you’re getting our product by the triangle shaped notch in one of the counterweights.

- The 4340 steel forgings are semi-finished, machined off-shore, then shipped to Callies to be finished.

- All Compstar components are 100% Mag Particle inspected to verify there are no cracks or inclusions in the material. Additionally, our in house metallurgical laboratory verifies material and heat treatment to ensure it meets Callies engineering and quality requirements.

- 100% of our Compstar crankshafts are finish sized and polished by American craftsmen, ensuring proper fitment and widths. Additional items checked are runout, bolt holes and oil holes.

- Every crank then goes through our stringent Quality Control final check, guaranteeing your Compstar Engine Component is ready to race.

Beginning with properly placed counterweights that not only improve balance but reduce bearing loads, every aspect of these highly stressed components has been analyzed. Our forgings are rough machined in a process that includes double stress relief operations that make these crankshafts very dimensionally stable.

Hardened with a deep nitride, Compstar cranks are ideal for all types of abusive racing environments. All rod journals are drilled and counterweights are profiled for piston clearance. With our consistent grind and polish, along with our precise stroke and index, you will see why we say these crankshafts are Compstar Correct.

Compstar crankshafts are available in a variety of configurations.