Lightweight Small Block Chevy

The Compstar Comet is your answer to lightweight crankshaft needs for Small Block Chevy engines. Produced from 4340 forged steel that is triple heat-treated and nitrided, Compstar Comets are ready for long term, trouble free use.

Each Comet features gun drilled mains, lightened rods, pendulum cut counterweights, and a star flange. All journals are polished to 5Ra or finer and match sized to within .0003 inch or less throughout the entire crankshaft. Comets are produced with .125 journal radii and require performance grade bearing inserts. Currently, Comets are only available with 350 mains.

Compweight Big Block Chevy

Drawing from the deep history of experience at Callies, our Compstar engineers have been able to combine the best characteristics of performance crankshaft design into the Compstar “Compweight” for Big Block Chevy applications Produced from 4340 material that is triple heat treated and stress relieved during machining. Compstar BBC Compweights will remain true during severe duty use.

All Compstar Compweights are center counterweighted for reduced bearing loads during high RPM use. Machined with .125 journal radii and conventional straight shot oiling, these cranks offer simple durability. With all 4 rod journals drilled, Compstar BBC Compweight cranks weigh in at 75lbs or less. Compweights are fully deep case nitrided.

LSX engines are taking the performance market by storm. To answer the needs of engine builders who are testing new limits, Compstar has developed the widest range of LSX crankshafts available anywhere. Regardless if your application is road race, marine, circle track, or street/strip, Compstar has the configuration you need.

Made from 4340 steel that is deep nitrided for strength and wearability, every Compstar crank is intended for high output installation. Compstar LSX crankshafts are counterweighted for enhanced bearing load distribution, which allows these shafts to withstand both high boost and high RPM applications.

Machined with large journal radii, gun drilled mains, and fully lightened rod journals, the Compstar LSX crankshaft is truly built for performance. To accommodate your engine control system, Compstar LSX shafts can be specified with either late LS2 – LS7 58 tooth or the early LS1 – LS6 style twin timing wheels. If you are building a dry sump LS7 style engine, Compstar offers an extended length post to easily complete your project.

Compstar LSX – 8 Counterweight cranks are sold rough balanced to 1850 grams, or finish balanced to your bob weight.

Ford Coyote engines have proven their exceptional capabilities both at the track and on the street. Callies Compstar 4340 Steel Crankshafts were designed to support the additional horsepower and torque being generated in these applications. These cranks are machined with large strength enhancing journal radii like all Compstar crankshafts and come nitrited. These cranks are available in three configurations. A stock 92.7mm stroke with “Standard” Coyote Rod journal, a 96.5mm (3.800″) stroke and a 99.06mm (3.900″) stroke. All standard OEM driveline, valvetrain and accessory components can still be utilized.

Every aspect of this crank has been meticulously engineered. It starts up front with a post that is dual keyed to securely locate supercharger drive pulleys, and ending with journals that are super finished. For ease of assembly, rod journals are standard SB Chevy diameter and width. Counterweights have been profiled for 6.125 inch connecting rods.

Compstar Hemi cranks are manufactured from 4340 steel and range in stroke from 3.800 – 4.080. Also for improved crank case ventilation and reduced weight, main journals are gun drilled.

All Compstar Hemi crankshafts are shipped with your choice of reluctor to meet your vehicles need.

Compstar billet crankshafts for the Viper are meant for hardcore race applications. These shafts are machined from 4340 steel for durability and nitride surface hardened for excellent bearing life. Compstar Viper V-10’s are produced with 2.100 Chevy rod journal diameters and widths, and are available with either 10mm or 7/16 flange threads. Strokes available will be 4.200” and 3.960”. Compstar Viper V-10’s can be ordered with a (60-2) notch tone wheel configuration.

Callies Durastar crankshafts are designed to be substantially stronger than OEM shafts currently found in GM’s popular Duramax diesel. This improvement is the result of substantially stronger steel, considerably deeper nitride layer and unique machining features.

Durastar crankshafts are intended to be externally balanced with stock damper and flywheel configurations.

Designed for Maximum Effort engines, all SS (Sport Series) crankshafts are finished with the same care and detail as the entire line of Compstar crankshafts. All SS cranks are sold balanced, ready for assembly. SS crankshafts by Compstar feature the best metallurgy and heat treatment on the market today.

Premium grade material, design and craftsmanship set Sport Series components for Subaru engines apart from other manufacturers of high performance engine components. Every Subaru component is meticulously inspected prior to shipment. When combined with world class material and design, this final attention to detail ensures you are getting the reliability you expect from every Callies product.

Billet and Forged Crankshafts for the Mitsubishi 4G63 are now available from Callies Performance Products. These 4340 material crankshafts are metallurgically and geometrically certified to the same quality standard of all Compstar by Callies crankshafts. These 4G63 crankshafts feature Twin Shot rod journal oiling and are available with race proven Aeroshed super finishing.

Honda Sport Series connecting rods are available with either ARP 2000 or Custom Age 625 bolts for High Output applications. All Sport Series rods are H-beam design machined from fine grained steel. Wrist pin bushings are of deformation resistant Ampco 18 material.

Intended for High RPM, High Output engines all Honda Sport Series crankshafts are finished with the same care and detail as the entire line of Compstar crankshafts. All SS cranks are sold balanced and ready for assembly. SS crankshafts by Compstar feature the best metallurgy and heat treatment on the market today.

Machined as an enhancement to the formidable Toyota 2JZ engine, Compstar Sport Series crankshafts are your best choice for extreme durability. Beginning with high grade 4340 steel and finished with the proven Callies premium in house nitride treatment these crankshafts are start to finish the best available in today’s market. Available in three strokes, all 2JZ shafts are machined to accommodate standard rod and main journal sizes.

All SS cranks are sold balanced, ready for assembly. SS crankshafts by Compstar feature the best metallurgy and heat treatment on the market today.

Ultra-Assassin rods are made entirely in the U.S.A. Every Ultra connecting rod is produced from specially formulated TimkenSteel 4330V grade steel. This material is then precision forged in Michigan and machined in our Fostoria, Ohio facility. Assassin Series Rods are near net as forged rod with minimal machining. Assassin Series rods are fastened by high alloy cap screws made specifically for severe duty service by ARP Inc. To eliminate deformation and extrusion only AMS 642 bronze alloy is used within the wrist pin housing bore.

Callies Ultra Enforcer connecting rods are produced from extremely clean TimkenSteel Product that is formulated to our exact specifications. This proprietary steel is forged in Trenton, Michigan, and manufactured 100% in our Fostoria, Ohio facility. Pride in workmanship, and attention to detail are qualities you’ll discover during careful examination of our finished product. Each step of the manufacturing history of every Ultra connecting rod is meticulously maintained by our manufacturing team. You can be confident of the material and workmanship of these quality components.

Designed with fortified tower flanges, Enforcer I-beam connecting rods are the ideal component for turbo charged and super charged engines.

Ultra connecting rods are made entirely in the U.S.A. Every Ultra connecting rod is produced from specially formulated TimkenSteel 4330V steel. This material is then precision forged in Michigan and fully machined in our Fostoria, Ohio facility.

Many geometric nuances have been incorporated into the design of Ultra connecting rods. These design features enhance the Ultra against specific loads and stresses which are applied to connecting rods subjected to high load, high RPM applications. Ultra connecting rods are fastened by high alloy cap screws made specifically for severe duty service by ARP Inc. Produced with rolled threads, these unique bolts offer improved thread engagement for a smoother more consistent net clamping load. To eliminate deformation and extrusion only AMS 642 bronze alloy is used within the wrist pin housing bore.

Ultra I-Beams are available in our standard weight version for extreme duty racing applications of popular Big Block Chevy, Small Block Chevy, Chevy LS, Big Block Ford, Small Block Ford, RY45, Ford Modular, Nissan GTR, Buick 3.8, as well as lightweight versions for select SBC configurations. For superior clamping, a Custom Age bolt upgrade is available for all Callies I-Beam connecting rods.

Callies Ultra connecting rods are produced from extremely clean TimkenSteel that is formulated to our exact specifications. This proprietary steel is forged in Trenton, Michigan, and manufactured 100% in our Fostoria, Ohio facility. Pride in workmanship, and attention to detail are qualities you’ll discover during careful examination of our finished product. Each step of the manufacturing history of every Ultra connecting rod is meticulously maintained by our manufacturing team. You can be confident of the material and workmanship of these quality components.

The Ultra H-Beam configuration was recently added as part of our expanding connecting rod line. Made from the same premium grade TimkenSteel material, the Ultra H-Beam connecting rod is designed to satisfy the requirements of the most demanding racing applications.

Callies is pleased to introduce the Ultra XD connecting rod. This unique patent pending configuration is designed for additional cam to rod clearance in long stroke Big Block and Small Block Chevy racing engines. In most cases, the XD connecting rod will provide approximately .050″ more cam clearance than our conventional Ultras, and substantially more over many of our competitor’s connecting rods.

Compstar engineering leads the way in High Value connecting rod design. The original Compstar H-beam rods were conceived around the idea that high quality and affordability can come in the same package. The time saved in preparation for use becomes an added value that you’ll discover during your engine build. Dimensional repeatability and the proper clearances for high performance use right out of the box also add value, as well as peace of mind. Attention to detail has long been the trademark of Compstar rods.

If you don’t see your Compstar H-Beam Connecting Rod listed here, check our Compstar Sport Series line or our new Compstar Xtreme line.

Designed and produced with engineering and finished advancements taken from our Ultra and Compstar rods. Compstar UTV connecting rods have what it takes to make your engine build trouble free and your finished product reliable. Produced from heat treated and stress relieved 4340 material, our H-beam Compstar rods are fully machined with a shot blasted Stress Riser free surface. Finished and sized in our plant in Ohio, every detail of this highly stressed component has been carefully analyzed to maximize dependability. All UTV rods have ARP Fasteners.

The next step in the Compstar line up. All the quality, reliability and workmanship you have relied upon for years from the Compstar line up is taken to the Xtreme. Specifically designed for power adder and diesel applications. The Compstar Xtreme utilizes the same proven 4340 material and ARP 2000 or L19 fasteners. Strength is added by thickening up the flanges of the H beam and a reduced depth of cut towards the center of the rod. Then non-essential weight is taken out of the beam to help keep the overall weight of this rod in check.

| 6.0 Powerstroke | Duramax |

| Big Block Chevy | BMP 409W |

| Gen III Hemi | Godzilla |

| LS 3-Bolt | Small Block Chevy |

| Small Block Ford |

Carburized & Hardened 8620 steel camshaft cores are produced to AMS 2301 (AQ) standards. Our engineering staff can create an unground lobe profile to your exact requirement. Carbocore cams are machined and heat treated entirely in house.

Callies Indurocore camshaft cores can be machined to your specification from either 1050 or 4150 alloy steel. Every Indurocore cam is induction hardened in house at Callies. This process is carefully monitored, guaranteeing metallurgical consistency. Indurocore cams are available for a wide range of engines.

Callies metallurgy and heat treat teams have perfected a revolutionary process that offers unrivaled camshaft durability. Titan Tool Steel Camshafts give you more options for performance, enhancing geometry while increasing life expectancy. Fully finished Titan cams are available for a wide range of engines and applications.

Carburized & Hardened 8620 steel camshaft cores are produced to AMS 2301 (AQ) standards. Our engineering staff can create an unground lobe profile to your exact requirement. Carbocore cams are machined and heat treated entirely in house.

Callies Indurocore camshaft cores can be machined to your specification from either 1050 or 4150 alloy steel. Every Indurocore cam is induction hardened in house at Callies. This process is carefully monitored, guaranteeing metallurgical consistency. Indurocore cams are available for a wide range of engines.

Callies metallurgy and heat treat teams have perfected a revolutionary process that offers unrivaled camshaft durability. Titan Tool Steel Camshafts give you more options for performance, enhancing geometry while increasing life expectancy. Fully finished Titan cams are available for a wide range of engines and applications.

Valve Train Group – VTG is the finish ground series of camshafts manufactured by Callies Performance Products. We offer cams to serve a wide variety of applications for many popular engine platforms.

VTG cams are available in multiple types of aircraft quality materials. Less aggressive profiles fit nicely within our induction hardened 1050 or 4150 materials. 8620 carburized material works well for many racing applications. Tool steel is available for the most extreme applications.

Keeping the valvetrain under control is vital to a successful engine program. Our lobe profiles are designed to produce excellent power without sacrificing durability. They are precision ground in our Landis CNC grinders, with event timing and lobe profile tolerances verified in our Adcole inspection gages.

With a long history of superior quality grinding experience, VTG by Callies is the right choice for all of your camshaft needs.

Valve Train Group – VTG is the finish ground series of camshafts manufactured by Callies Performance Products. We offer cams to serve a wide variety of applications for many popular engine platforms.

VTG cams are available in multiple types of aircraft quality materials. Less aggressive profiles fit nicely within our induction hardened 1050 or 4150 materials. 8620 carburized material works well for many racing applications. Tool steel is available for the most extreme applications.

Keeping the valvetrain under control is vital to a successful engine program. Our lobe profiles are designed to produce excellent power without sacrificing durability. They are precision ground in our Landis CNC grinders, with event timing and lobe profile tolerances verified in our Adcole inspection gages.

With a long history of superior quality grinding experience, VTG by Callies is the right choice for all of your camshaft needs. Together with Energy Manufacturing Ltd. (Energy), Callies Performance Products (Callies) announces a new licensing deal with Fiat Chrysler Automobiles to manufacture and distribute the 426 Hemi and the 440 Wedge cast iron engine blocks and cylinder heads (cast iron and cast aluminum). The agreement provisions Energy to produce the cast iron blocks and cylinder heads while Callies, their sister company, will manufacture supporting componentry and rotating assemblies. Sales and distribution will be based at Callies in Fostoria, Ohio.

All parts manufactured will carry authentic Mopar part numbers and be produced from original Mopar molds, cores, and engineering data.

For questions, builders and racers should contact Callies by calling their sales office at (419) 435-2711.

Energy Manufacturing billet blocks begin life as a 490 pound block of high grade forged 6061 aluminum. Featuring rolled thread tapped holes for extra strength and high strength cylinder liners, careful attention is given to fit and finish of the overall block. Each semi-finished block is thoroughly heat treated to T6 standards.

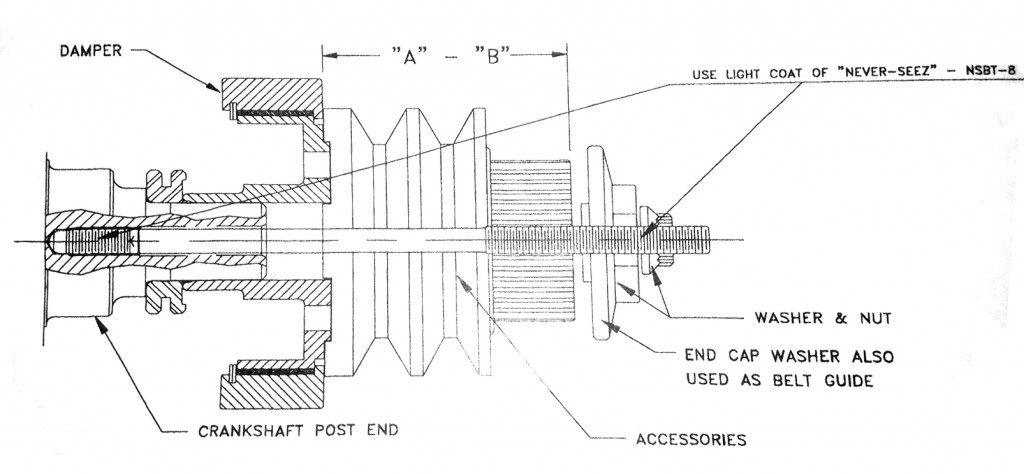

Callies designed this high quality stud kit specifically for use with our crankshafts employing deep hole post drilling. The kits are available in various lengths to suit a variety of crankshaft post driven accessory drives.

-The kit consists of a roll-threaded stud, parallel ground washer, and 12-point nut, all made of 8740 moly steel.

-Intended as a great companion item, Callies has developed a hex head hat washer that will simplify turning over the engine. It is manufactured from 8740 material, heat treated to 40Rc, and designed to allow a bolt head or nut to fit within its thickness, making it ideal for use in tight quarters.

| DAMPER STUD, WASHER & NUT KITS | ||

| CPPI-013D | 7/16 x 5.409 damper stud kit | |

| CPPI-013E | 7/16 x 8.396 damper stud kit | |

| CPPI-013F | 7/16 x 10.396 damper stud kit | |

| CPPI-013G | 7/16 x 6.396 damper stud kit | |

| DAMPER STUD KIT COMPONENTS | ||

| CPPI-013DS | 7/16 x 5.409 damper stud | |

| CPPI-013ES | 7/16 x 8.396 damper stud | |

| CPPI-013FS | 7/16 x 10.396 damper stud | |

| CPPI-013GS | 7/16 x 6.396 damper stud | |

| CPPI-013SS | 1/2 x 7.000 damper stud | |

| CPPI-021B | 7/16 ID, 2.125 OD stud washer, w/ hex nut | |

| APN12-1 | 7/16 12 point nut | |

1. Make sure threads in crankshaft are clean and are good threads.

2. Lightly coat the end of the stud going into the crank with “NEVER-SEEZ” (note: “Never-Seez” is the only material to be used!)

3. Install stud with 15 ft./lbs. of torque. DO NOT use any Loctite type products.

4. Install damper and accessories.

5. Install .300″ thick washer. Make sure the surface the washer is going against is parallel.

6. Lightly coat threaded area where the nut goes and coat the bearing surface of the nut with “NEVER-SEEZ.”

7. Install nut using 75 ft./lbs. of torque. (except CPPI-013F use 65 ft./lbs. of torque)

| Stud Kits Available: | “A” – “B” Dimension | Correct Stud Kit |

| (Kit Includes 6pt. Nut, .300? Thick Ground Washer & Stud) | 0.770″ to 0.832″ | CPPI-013D 7/16″ x 5.409″ |

| 0.803″ to 1.819″ | CPPI-013G 7/16″ x 6.396″ | |

| 1.640″ to 3.819″ | CPPI-013E 7/16″ x 8.396″ | |

| 3.042″ to 5.819″ | CPPI-013F 7/16″ x 10.396″ |

Let the professionals at Callies pair your crankshaft with all the proper bottom end components. Fully balanced and ready to assemble rotating assemblies from Callies not only save you time and money, they provide the peace of mind that your components are matched for compatibility, giving you a trouble free project.

Due to the vast offerings of parts and individual needs, no two speed packs are the same. Formulating your engine combination is a highly consultative process. Before contacting our technical department, please have the following information, desired cubic inches, desired compression ratio, cc of the cylinder heads, final bore and deck height.

Our technical staff is ready and willing to assist you.

Callies tungsten heavy metal is specially machined to ease installation and produce an excellent appearing product. Our HM slugs are center-less ground, then precision turned to length and chamfered. The result is unmatched dimensional consistency.

Wide ranges of lengths are available to specifically match the variety of counterweight thicknesses found on Chevy, Mopar, and Ford crankshafts. Diameters from 0.500″ up to 1.3770″ make locating the exact weight much easier.