Callies Ultra connecting rods are produced from extremely clean TimkenSteel product, that is formulated to our exact specifications. This proprietary steel is forged in Trenton, Michigan, and manufactured 100% in our Fostoria, Ohio facility. Pride in workmanship, and attention to detail are qualities you’ll discover during careful examination of our finished product. Each step of the manufacturing history of every Ultra connecting rod is meticulously maintained by our manufacturing team. You can be confident of the material and workmanship of these quality components.

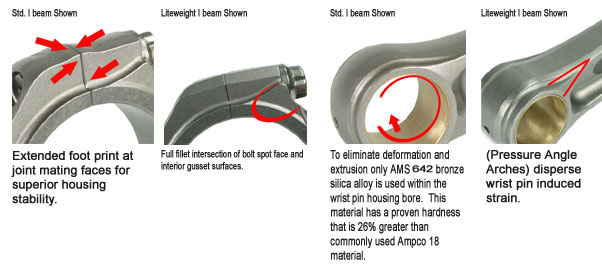

Ultra I-Beams are available in our standard weight version for extreme duty racing applications of popular Big Block Chevy, Small Block Chevy, Chevy LS, Small Block Ford, Big Block Ford, and Nissan GTR, as well as lightweight versions for select SBC configurations. For superior clamping, a bolt upgrade to Custom Age 625 material is available for all Callies I-Beams.

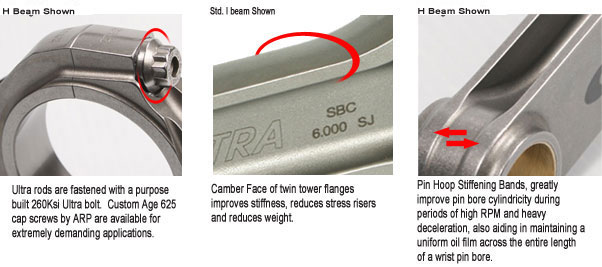

The Ultra H-Beam configuration was recently added as part of our expanding connecting rod line. Made from the same premium grade TimkenSteel material, the Ultra H is designed to satisfy the requirements of the most demanding racing applications.

Callies Ultra XD rods are designed for extra cam clearance on long stroke applications. The canted fastening system allows the use of a larger base circle cam for increased valve train stability, more lift using the same base circle, or longer stroke.

Compstar rods are started overseas, but are made from forging dies owned by Callies. Our Compstar rods are finish sized at our plant in Fostoria, Ohio and all critical dimensions are verified. Like all our products they fully designed and engineered by Callies. For more information on Compstar click here.

Increased Stroker Clearance – The best bolt to block & rod to cam clearance in the industry for long stoke applications.

Bolt Spotface Gussets – Allow optimized bolt location without loss of strength or defomation of the big end bore.

100% Thread Engagement – Assures no bolt threads are left exposed in the area between the bolt thread and shank.

Specifically Designed, 260Ksi Ultra Bolts – All Ultra bolts are designed to fit each specific connecting rod. Rolled threads are employed to provide improved engagement for a more consistent clamping load. Callies provides and recommends the use of ARP Ultra torque lube. For a complete listing of recommended torque & stretch data, please visit our Rod Bolt Torque page.

*Pin ends are on center for all parts