Callies Performance Products would like to introduce you to Compstar.

Compstar components were introduced in 2004 as a product line designed to meet and exceed the requirements of today’s racer at a sensible price point. Callies’ value driven approach is to design and engineer here in the U.S., then source through long term vendors, supported by our engineers, giving us distinct technical and quality advantages. This coupled with our American craftsmen, that finish the components at our facility in Fostoria, Ohio, create a combination that is considerably more robust and stable than our competitors. We are not just an importer of product, we are a manufacturer that wants to bring products to our customers at all price points.

Crankshafts

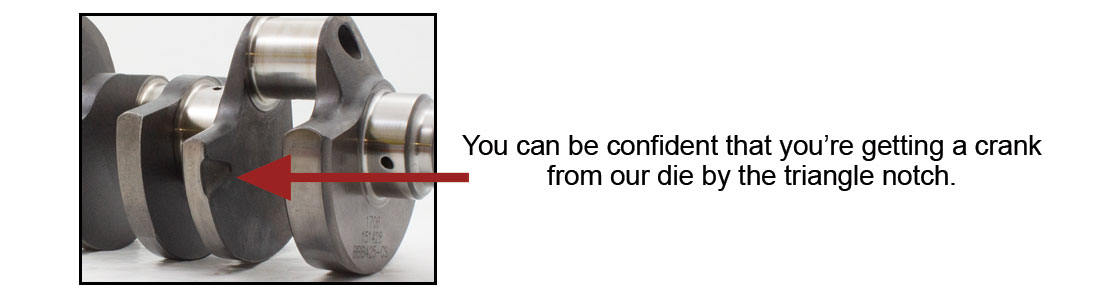

- Compstar crankshafts begin their life overseas where they are forged using Callies owned dies. Not generic forging that other manufacturers use. You can be confident that you’re getting our product by the triangle shaped notch in one of the counterweights.

- The 4340 steel forgings are semi-finished, machined off-shore, then shipped to Callies to be finished.

- All Compstar components are 100% Mag Particle inspected to verify there are no cracks or inclusions in the material. Additionally, our in house metallurgical laboratory verifies material and heat treatment to ensure it meets Callies engineering and quality requirements.

- 100% of our Compstar crankshafts are finish sized and polished by American craftsmen, ensuring proper fitment and widths. Additional items checked are runout, bolt holes and oil holes.

- Every crank then goes through our stringent Quality Control final check, guaranteeing your Compstar Engine Component is ready to race.

Connecting Rods

- Compstar and Compstar Sport Series are forged overseas on Callies owned dies. They are not run on the community dies shared by many others.

- The 4340 steel forgings are semi-machined off-shore and then shipped to Callies to be finished.

- Metallurgical checks confirm the material and heat treatment complies with our specifications.

- 100% of the parts are washed, Callies purchased ARP fasteners are installed and torqued, and parts are honed by our American craftsmen to final sizes.

- Samples from each lot are checked in our Quality Control lab for adherence to our strict specifications, and also checked for bend and twist. Parts are weight matched into sets creating consistency for the engine builder.

So why buy a Compstar over the competition? Because at Callies Performance Products you’re buying from a proud, independently owned American manufacturer. …. Not a “manu-packager.”

See a complete product list here!